Stoke Space’s Next Development Test Series: Hopper2

We recently shipped our reusable second stage prototype, the Hopper Test Vehicle, to our test site in Moses Lake, Washington. We’re calling this unit Hopper2. Over the next few weeks, we’ll be conducting a series of system tests including Wet Dress Rehearsals (WDRs), countdown automation, and static stage hotfire. These will culminate in attempting a vertical takeoff and vertical landing (VTVL) flight test.

While we’re hopeful that Hopper2 will successfully complete this full series of tests, including a flight test with the vehicle upright and intact upon landing, there’s a good chance that won’t be the outcome. And that’s okay. With developmental tests of this nature, we’re pushing the hardware to its limits so we can obtain data that will help us refine the prototype’s engineering and design.

Earlier this spring, we took a similar approach with our Hopper1 tests. In that developmental campaign, we learned a lot about our fluid systems, propellant conditioning, operational procedures, and terminal count. What we learned led to design changes that are now in place with Hopper2.

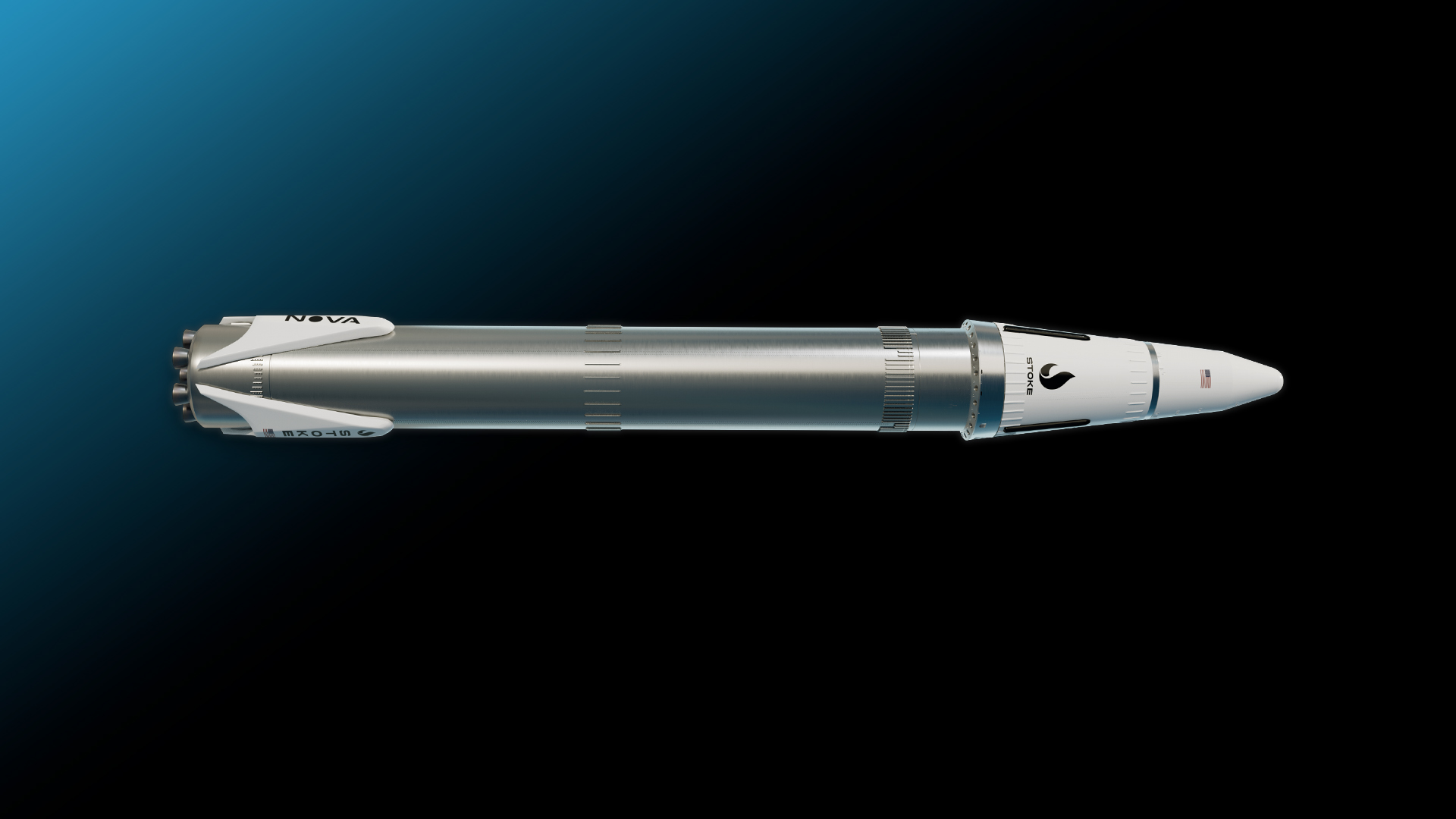

Stoke’s design for its second stage is something completely new. With the Hopper development test program, we intend to demonstrate our novel engine and thrust vector control via differential throttle, as well as our avionics, software, and ground systems. Ultimately, the purpose of these developmental tests is to directly inform the orbital rocket designs and bring us one step closer to delivering payloads to, through, and from orbit.